Aerosol industry

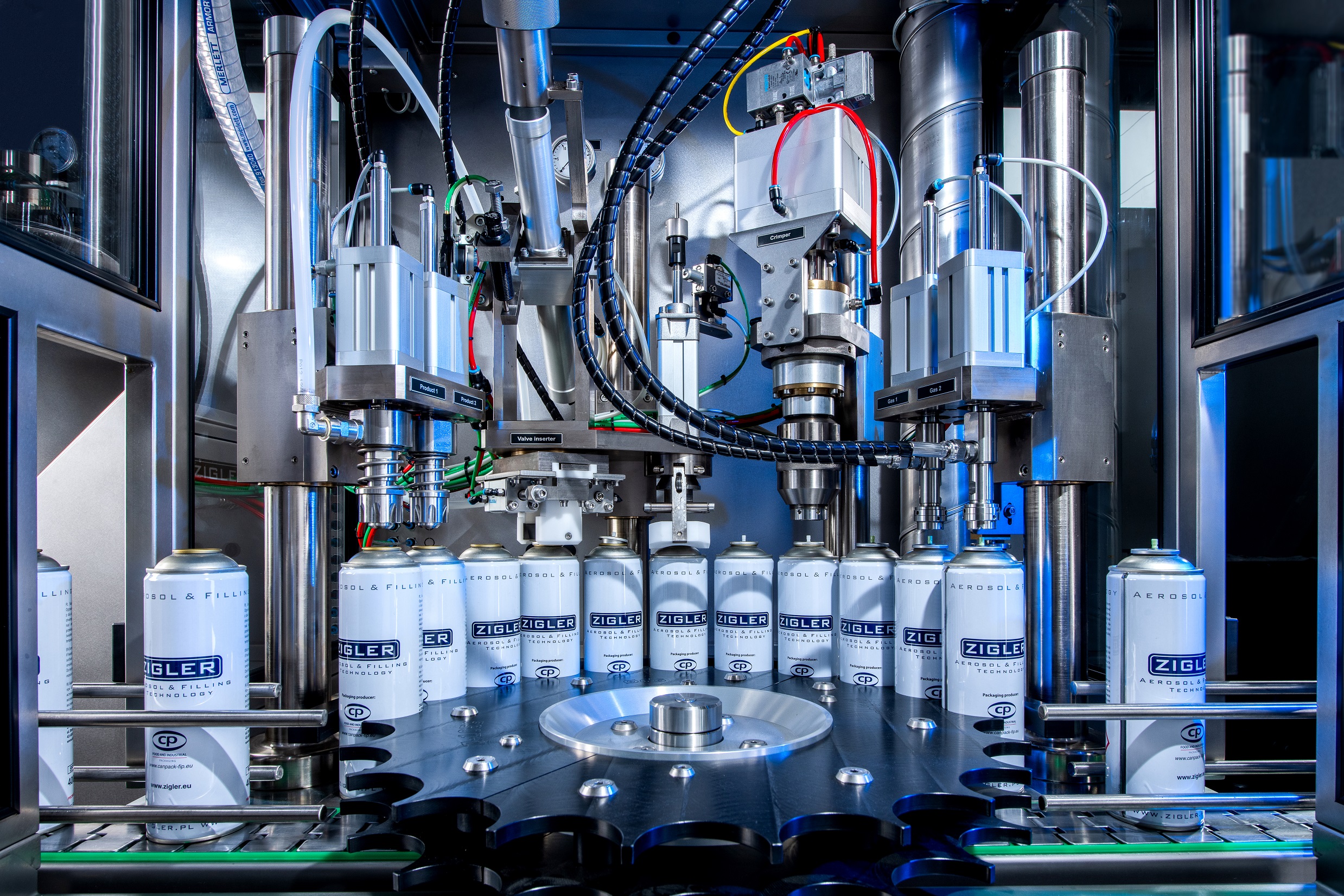

ZIGLER - machine manufacturer

and devices for filling products in the form of aerosols and products in packages with sprayers.

Since 2009

ZIGLER offer also includes specialized filling lines and cappers,

requiring the use of ATEX standards. In 2013 ZIGLER established a development department

devices for the pharmaceutical industry. Thanks to this, the ZIGLER offer is now also

addressed to manufacturers of pharmaceutical products in aerosol packaging and not only!

ZIGLER's main goal is to produce machines of the highest quality. Continuous development

the latest technology and the use of appropriate components gives us such opportunities.

Thanks to this, the ZIGLER brand is now perfectly recognized and appreciated by customers around the

world. Our

The devices are already in operation in more than 40 countries around the world. Qualified

engineering staff, the best

designers in the industry, developing aerosol devices for over 30 years, and very advanced

design department working on the highest quality software in accordance with

ISO 9001:2015 procedures mean that ZIGLER products are subject to the standard

24 months warranty. The ZIGLER team has over 50 people. Extensive, over 30 years of experience

management personnel accumulated in many implementations of product lines, allows

create ever larger, "custom" projects for individual needs

clients.

We build each line to order, taking into account the specifics of the

production of our

clients.

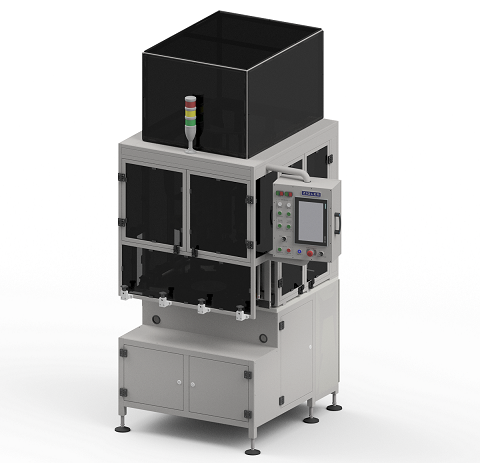

Device Z-1084 is designed for automatic spraying

aerosol caps which, due to their asymmetric geometry and integrated

graphic pattern require orientation (rotation) in relation to the aerosol can, on

which they wear.

Vision system based on Omron components (sensor, lens

and illuminator) is designed to recognize the position of the cover relative to the marker on

container, which allows you to determine the angle of rotation given to the head, equipped with a

vacuum

lid holding grip.

The movement of the gripper tip is carried out by magnetic

linear rotary actuators LinMot. The machine is equipped with Mitsubishi servo, indexing

containers with double pitch, so 2 lids are oriented and placed in one cycle

simultaneously - all systems are duplicated (vision system, vacuum gripper, magnetic

drives). The rotation of the head in each grip is carried out by JVL servo drives. Whole system

controlled by a special PLC Siemens series S7. Simatic HMI panel equipped with 12"

touch screen, is responsible for communication with the operator.

Through complete

automation of all

cycle, all settings are software-only, starting from the touch interface level. Usage

router Asem allows for comprehensive remote diagnostics using

Ethernet interface or 3G/4G.

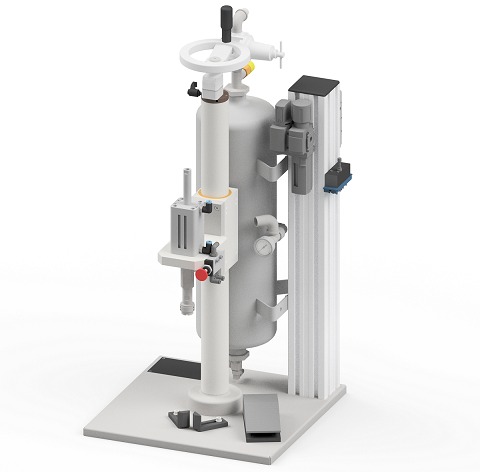

Z-2013 semi-automatic CO2/N2 filling device presents

is a device used to fill aerosol cans with N2/CO2 in gaseous form

through pinch aerosol valve.

The device is powered and controlled only by compressed

air

and equipped with a gas storage tank.

The filling pressure is limited to 1.6 MPa (16 bar). The machine can work with aerosol valves

or Bag-On-Valve in standard 1″.

Пif necessary, the machine can be delivered

in GMP compliant version with all steel parts that come into

direct contact with the product, in AISI 316L steel, and all seals are made of

pharmaceutical/food approved materials.

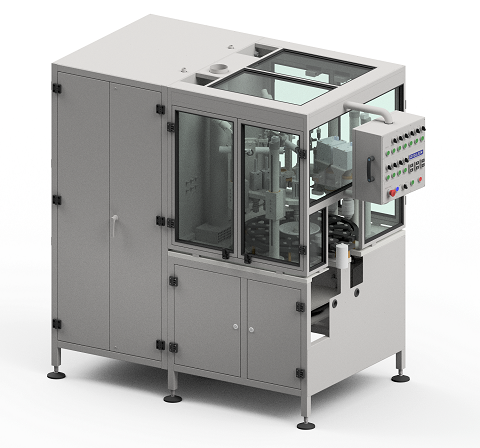

The AIM 1031 automatic indexing module is part of

automatic line for the production of aerosols and is designed for the following stages of

production:

43-600 Jaworzno

ul. Braci Gutmanów 7

Polska

tel.:

+48 32 616 36 70

tel.:

+48 600 248 300

tel.: +48 600 248 400

sekretariat@zigler.pl

biuro@zigler.pl

zigler.eu/